- Home

- Bio & Circular

- RECYCLE

- Mono-material Packaging

-

RECYCLE

Mono-material Packaging

-

RECYCLE

Mono-material Packaging

- Home

- Bio & Circular

- RECYCLE

- Mono-material Packaging

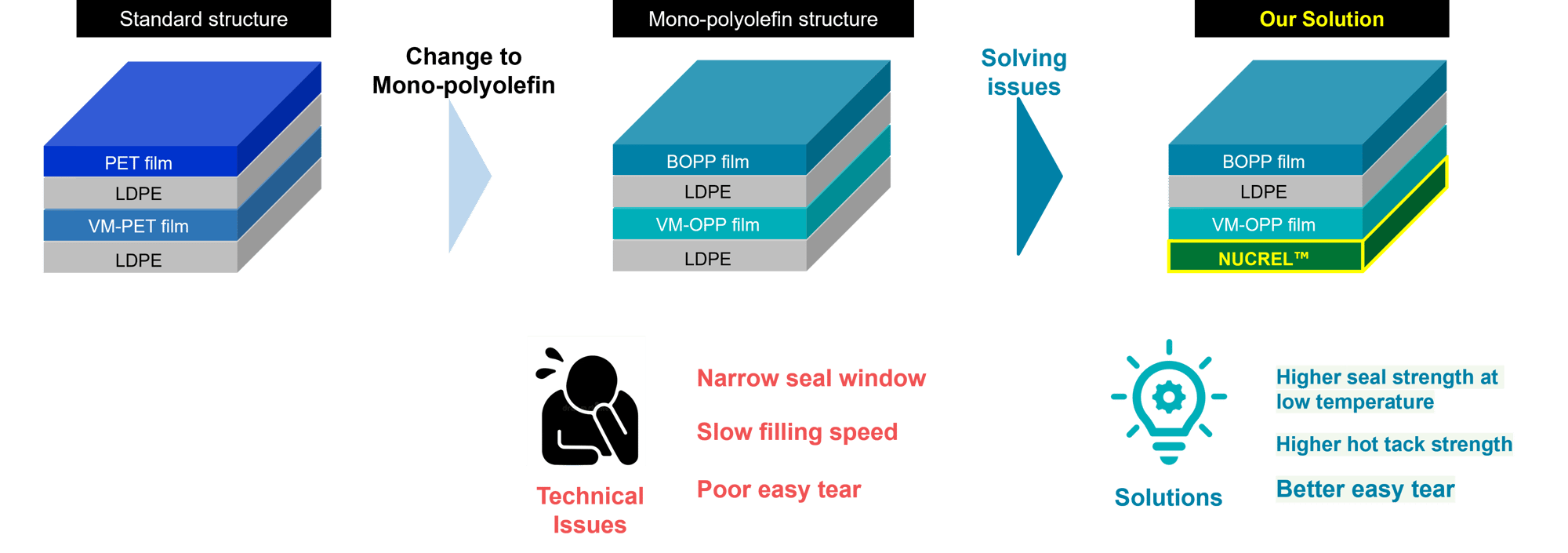

As one of the eco-friendly solutions for packaging, there is a trend to change film structures using some different materials to mono-polyolefin structures aiming to improve recyclability. However, typical mono-olefin packaging structures tend to face technical issues such as sealability, fillability and tearability. By using our product NUCREL™ as a seal layer, such technical issues can be solved.

As one of the eco-friendly solutions for packaging, there is a trend to change film structures using some different materials to mono-polyolefin structures aiming to improve recyclability. However, typical mono-olefin packaging structures tend to face technical issues such as sealability, fillability and tearability. By using our product NUCREL™ as a seal layer, such technical issues can be solved.

-

Our Proposal for Improved Mono-polyolefin Packaging

In case of varrier packaging using VM-PET film as a varrier layer, PET film as a substrate and LDPE or LLDPE as a seal layer, changing it to a polyolefin packaging by just changing varrier layer and substrate tend to cause technical issues of sealability, fillability and tearability. By changing seal layer from LDPE or LLDPE to our resin product NUCREL™ will solve those technical issues.

-

Our Proposal for Improved Mono-polyolefin Packaging

In case of varrier packaging using VM-PET film as a varrier layer, PET film as a substrate and LDPE or LLDPE as a seal layer, changing it to a polyolefin packaging by just changing varrier layer and substrate tend to cause technical issues of sealability, fillability and tearability. By changing seal layer from LDPE or LLDPE to our resin product NUCREL™ will solve those technical issues.

-

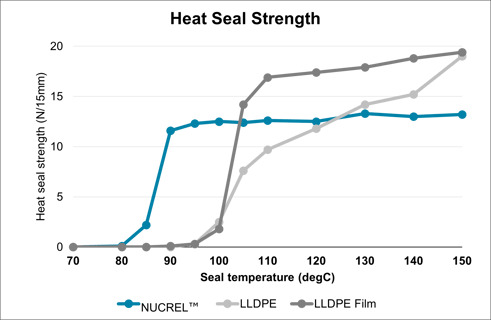

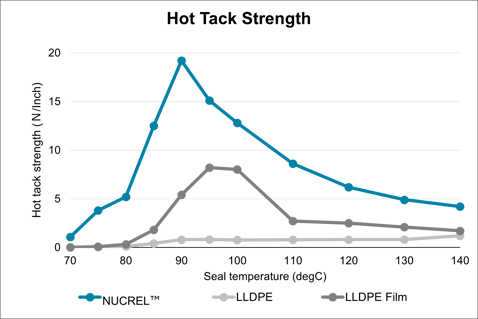

Seal Performances

By using NUCREL™ instead of LLDPE as a seal layer instead of LLDPE, sealing performance at low-temperature and hot tack strength are significantly improved.

-

Seal Performances

By using NUCREL™instead of LLDPE as a seal layer instead of LLDPE, sealing performance at low-temperature and hot tack strength are significantly improved. Sealing performance at low-temperature and hot tack strength are better than the structure using LLDPE film as a seal layer.

-

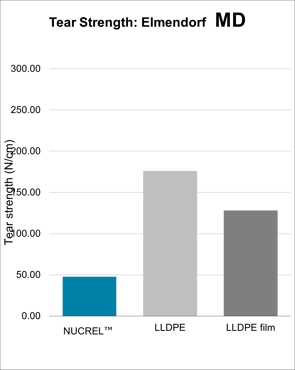

Mechanical Properties

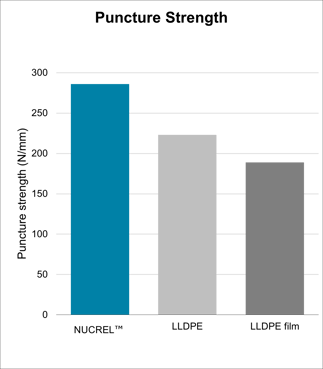

By using NUCREL™ instead of LLDPE as a seal layer instead of LLDPE, properties of easy tear in MD and puncture strength are improved while keeping the easy tear property in TD at the similar level. Easy tear properties (both MD and TD) and pucture strength are better than the structure using LLDPE film as a seal layer as well.

-

Mechanical Properties

By using NUCREL™ instead of LLDPE as a seal layer instead of LLDPE, properties of easy tear in MD and puncture strength are improved while keeping the easy tear property in TD at the similar level. Easy tear properties (both MD and TD) and pucture strength are better than the structure using LLDPE film as a seal layer as well.

-

Overview: Film Properties

By using NUCREL™ grades as a seal layer, seal performance and mechanical properties of mono-polyolefin packaging will be improved. The same can be said in the comparison to a fillm structure using LLDPE film as a sealant layer.

-

Overview: Film Properties

By using NUCREL™grades as a seal layer, seal performance and mechanical properties of mono-polyolefin packaging will be improved. The same can be said in the comparison to a fillm structure using LLDPE film as a sealant layer.

| Property |

Sealant Layer

|

|||||

|

NUCREL™

|

LLDPE

(Density 906)

|

LLDPE Film

(Low temperature seal type)

|

||||

|

Sealability Low Temperature

|

Far better

|

N/A

|

N/A

|

|||

|

Hot Tack Strength

|

Far better

|

N/A

|

Slightly better

|

|||

|

Seal Strength (120degC)

|

N/A

|

N/A

|

Far better

|

|||

|

Tear Resistance

Elmendorf method

|

MD

|

Far better

|

N/A

|

Slightly better

|

||

|

TD

|

N/A

|

N/A

|

Poor

|

|||

|

Puncture Strength

|

Better

|

N/A

|

Poor

|

|||

| Property |

Sealant Layer

|

||||

|

NUCREL™

|

LLDPE

(Density 906)

|

LLDPE Film

(Low temperature seal type)

|

|||

|

Sealability Low Temperature

|

Far better

|

N/A

|

N/A

|

||

|

Hot Tack Strength

|

Far better

|

N/A

|

Slightly better

|

||

|

Seal Strength (120degC)

|

N/A

|

N/A

|

Far better

|

||

|

Tear Resistance

Elmendorf method

|

MD

|

Far better

|

N/A

|

Slightly better

|

|

|

TD

|

N/A

|

N/A

|

Poor

|

||

|

Puncture Strength

|

Better

|

N/A

|

Poor

|

||